From the Factory | August 9, 2023

Coated Strings Versus Treated Strings

What’s the Difference?

Greetings, fellow guitar fans! Let’s be honest, we – each and every one of us – love our guitars. We want them to play and sound great, because when they do, we play and sound our best. Which brings us to the subject of guitar strings. The right strings are essential to unlocking a guitar’s full potential, both in tone and in ease of playing. We have lots of options when selecting a set of strings for our acoustic guitars, from materials to string gauges.

Two of those options are coated and treated strings, both of which promise long-lasting tone and impressive durability. Coated strings and treated strings often get lumped together, but differ significantly. So what’s the difference between coated strings or treated strings? We will delve into that subject in a minute.

First, a little history. Steel strings for acoustic guitars have been around more than 100 years. From the beginning, a set typically has consisted of two higher pitched strings made with plain steel and four lower pitched strings made with steel cores sheathed in a wrapped outer layer.

Uncoated strings have been with us the entire time but have evolved over the years. The original string wrapping was silvered steel, which produced a harsh, penetrating tone. By the 1930s, the steel wrapping was replaced by Monel, a nickel/copper alloy that sounded better and slowed corrosion. Additional string wrapping materials followed; Bronze (80% copper/20% tin; bright, crisp tone) and Phosphor Bronze (92% copper/7% tin/1% phosphorous; warm, full tone).

Coated strings were introduced in the 1970s but didn’t become widely available until the 1990s. The science behind coated strings is simple; strings coated with a polymer become more resistant to corrosion and oxidation, and therefore last longer. Makers of coated strings typically offer them in the same types, gauges and wraps as their uncoated strings.

While those three elements vary little, coating materials, coating thicknesses and coating processes vary widely from producer to producer. Most string makers have their own coating formula. The thickness of the coating varies from maker to maker – and occasionally within a maker’s offerings - as well. Sometimes only the wraps are coated before being wound on the cores. Sometimes the strings are coated after wrapping. Sometimes just the wound strings are coated. Sometimes all the strings – wound and plain - are coated.

Treated strings first arrived on the market in the late 2000s. The goal of treated strings is the same as coated strings; to prevent corrosion and oxidation, and thus extend the life of the strings. However, the approach is different. Instead of being coated, the strings are chemically treated at a molecular level. As a result, treated strings offer durability comparable to coated strings and playability comparable to uncoated strings. Typically both the wound and plain strings are treated. The materials and the technology involved to make treated strings are proprietary to each producer.

Appreciating the potential of treated strings, C.F. Martin & Co. invested early in research and development to create its own unique, patented string treatment process. It introduced Martin Authentic Acoustic Lifespan® strings in 2010. Continued Martin research and development resulted in the next generation Martin Authentic Acoustic Lifespan® 2.0 strings, which debuted in 2019.

Enough history. Before we get into the practical differences between coated and treated guitar strings, let’s take a look at their shared advantages.

Compared to traditional guitar strings, they last and keep their tone a long time. How long? That depends on your playing style, playing situation (hobby, gigs, recording, etc.) and body chemistry. For most players, coated and treated strings can last anywhere from two to five times longer than uncoated ones.

They can be budget friendly. Yes, they cost more than uncoated strings initially, but because they last so much longer, coated and treated strings often can save you money.

They reduce the amount of string noise (i.e. squeaks) from the fretting.

Last but not least, they simplify your life. Almost none of us enjoy changing strings. We may enjoy the results, but we don’t enjoy the task. So doing fewer string changes is great. Plus, it gives us more time to play.

Now the differences between coated strings and treated strings.

The biggest difference is tone. Coated strings have their own distinctive sound. They are not as loud and not as complex as uncoated strings. Nor do they offer the same volume and dynamic range. Last but not least, they typically dampen high notes, especially those played up the neck.

By contrast, treated strings sound identical to traditional uncoated strings; the same rich harmonics, the same long sustain, the same balance, the same volume and the same dynamic range.

Another difference is how each feels under your fretting hand. Coated strings are – by their nature – slippery. As a result, the possibility of a finger sliding off a string, especially when doing string bends or vibrato, is always there. However, the smooth surfaces of coated strings can be easier on the fingers, an important consideration if you are practicing a lot or playing long sets.

Treated strings feel like traditional strings, though users may notice a reduction in surface friction due to the treatment.

The coating on coated strings has a propensity – sooner or later – to flake. The coating can only handle the impact of the strings against the frets for so long. Treated strings do not flake, because the treatment is chemically bonded to the strings rather than applied to them.

The choice between coated strings or treated strings is a personal decision. You have plenty of factors to consider. Your tone preference. Your guitar. Your playing style. Your playing situation (solo, duo, band, personal enjoyment, professional gigs, recording, etc.). The right answer on choosing between coated and treated strings is the answer that is right for you.

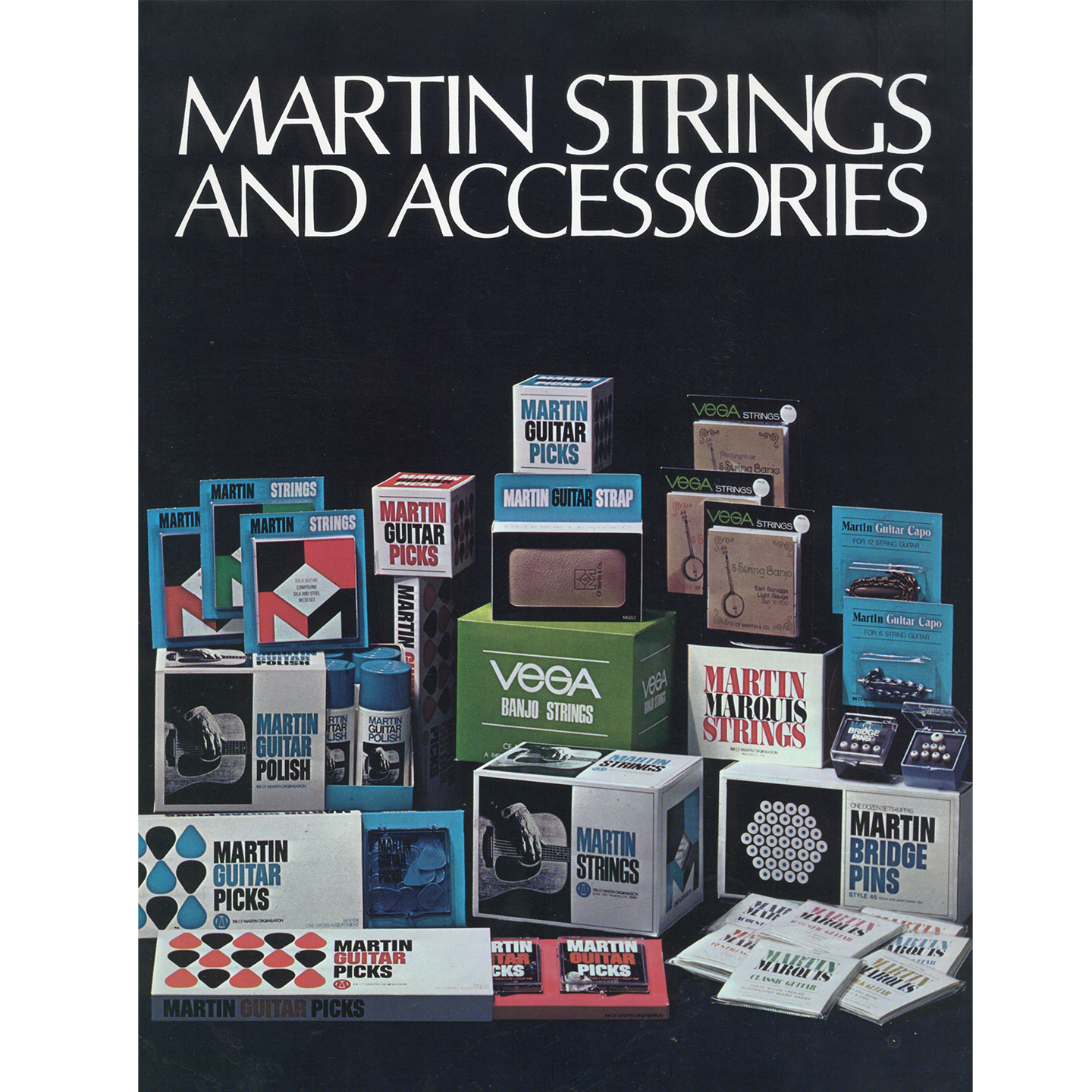

C.F. Martin & Co. is the only acoustic guitar manufacturer to also make its own strings. We realized more than 50 years ago the best way to ensure strings with utmost quality and consistency was to design and manufacture them ourselves.

We have the luxury of testing our strings on some of the world’s finest instruments. In doing so, we assure our innovations in string design and production bring out exceptional tone and nuance in every guitar. Our Martin Authentic Acoustic Lifespan® 2.0 Phosphor Bronze and Bronze strings may be the ultimate in great playing, long lasting acoustic guitar strings, but C.F. Martin’s other fine strings – from Martin Authentic Acoustic SP, Martin Marquis®, Martin Originals and Martin Retro strings, to Martin Flexible Core and Luxe by Martin® Titanium Core and Kovar™ SP Core® strings – assure you will find the perfect set of Martin strings for your guitar.